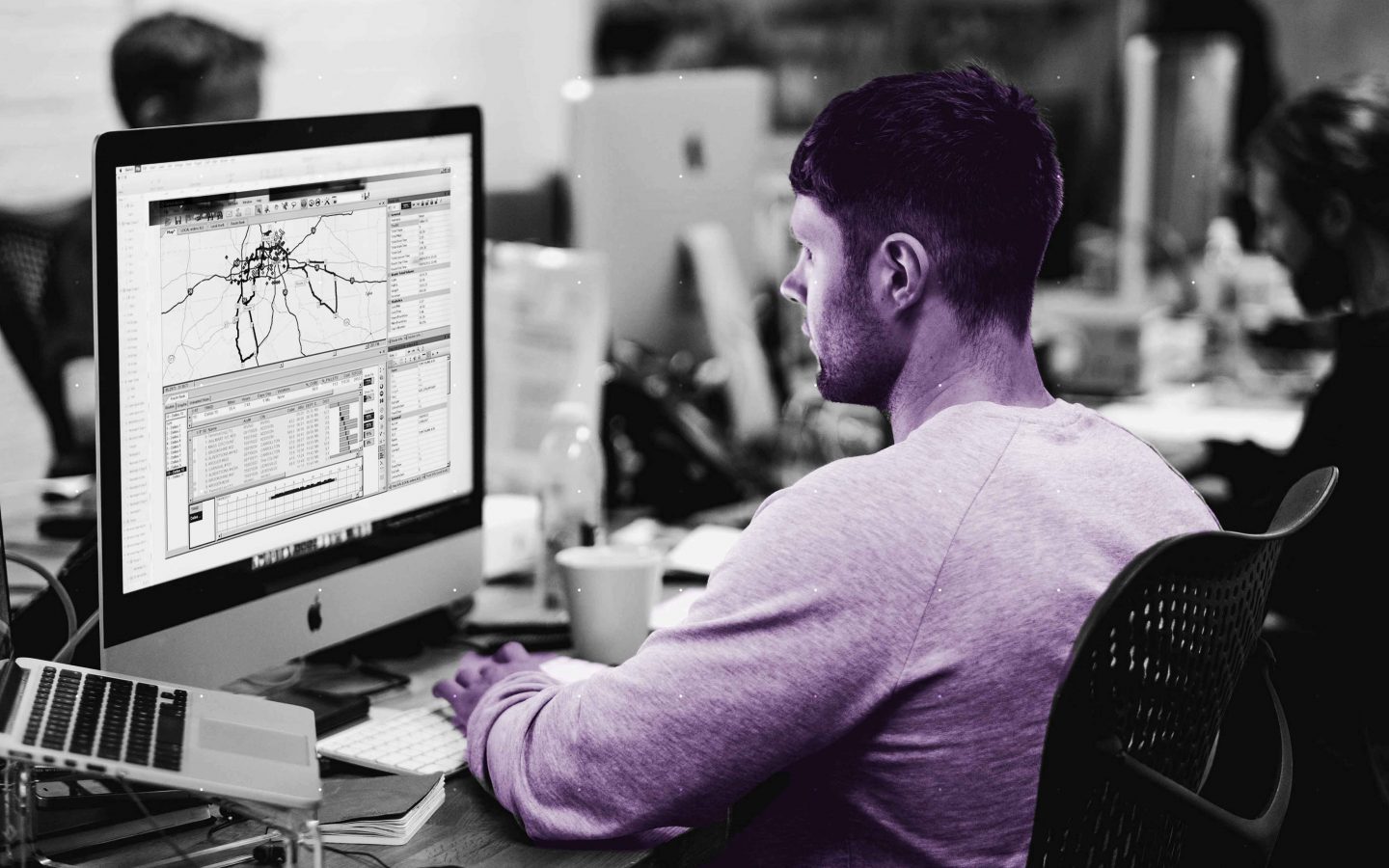

As specialists in retail disaster recovery logistics, the ENERGY team knows how to organize and execute a logistics plan.

Communication, strategy, and execution are critical to any successful retail disaster recovery plan.

Empathy is also important. It’s safe to say that in the retail disaster recovery business, you’re working with people who aren’t having the best of days.

But on our worst days, the best thing someone can offer you is experienced and capable help to get you swiftly back on your feet. ENERGY specializes in getting your business up and running quickly because we have the experience to ask the right questions and the expertise to get the job done.

Retail disaster recovery: Arson at three big box stores

It’s late November, and the team at ENERGY receives a midnight phone call about a job. But this call isn’t about just one job: it’s three.

The story is that three big box stores in the Toronto area were all set on fire in one night.

From our experience in the logistics of retail disaster recovery, we knew this would be a big project, and it couldn’t have happened at a worse time. November is peak season for shipping, making capacity tight, and demand for drop trailers goes through the roof. But this wasn’t our first rodeo, and the team knew we had to establish the proper lines of communication and make a strategy for execution.

Communication

Communicating across multiple channels effectively and efficiently with so many boots on the ground is the difference between a project that meets deadlines and one that doesn’t.

In this case, it was a tight reopening deadline. The rule with the big box store was that the three sites had to be ready for business in 12-15 days.

We needed to establish how much material needed moving, how quickly, and where it was going. We also needed to know what happens to the potentially fire-damaged merchandise. Can we sell it, or can we destroy it locally? If it needs to be hauled long distance, the carrier needs to know that and be ready for it.

But once all key personnel was identified, our communication channels established, and the scope of work, we were ready to make our game plan.

The game plan and execution

Since this job involved three separate stores, the number of drop trailers needed was substantial. We required 50 at each location, for a total of 150.

The logistics of three separate sites meant things could get complicated quickly.

The first thing we did was decide that I would work with a single carrier. We didn’t want to create confusion and complexity by adding multiple carrier partners to the job.

The second task was finding the 150 trailers we would need during peak season. We had to pull out all the stops to get those trailers.

We were getting trailers out of retirement and fixing others to make them roadworthy and ready for inspection — it was a huge undertaking and only two weeks to get it done.

Despite all the obstacles, we completed all three jobs on time and within budget. The company was so pleased with our work that when there was another fire at one of their locations in northern Manitoba, ENERGY was first on their list.

From disaster recovery and restoration to dry van, refrigerated, drop trailer, or cross-border freight, the team at ENERGY can help you optimize your supply chain. Contact us today.